Renewable biofuels have the potential to reduce U.S. dependence on imported oil, lower greenhouse gas emissions and further develop the rural economy. Ethanol production capacity is currently at 12 billion gallons per year and is overwhelmingly based upon corn processing. Yet because we consume 140 billion gallons per year of gasoline, corn ethanol can substitute for only about six percent of our gasoline needs on an energy basis. The Energy Independence and Security Act of 2007 sets the ambitious goal of expanding biofuel production to 36 billion gallons per year by 2022 (replacing 20 percent of our gasoline on an energy basis) and further specifies that 60 percent should be comprised of advanced biofuels, which includes biofuels produced from lignocellulosic biomass (LCB).

Lignocellulosic biomass includes such things as agricultural residues and processing byproducts like corn stalks, rice and wheat straws, and new dedicated energy crops like switchgrass. There is potentially 1.3 billion tons of this biomass available annually in the U.S.; that’s enough to replace nearly two billion barrels of oil per year (one barrel equals 42 gallons). This is equal to the total amount of oil the U.S. currently imports each year.

Unfortunately, producing ethanol from LCB is estimated to cost at least 70 percent more than producing ethanol from corn. Still, there are grounds to be optimistic because LCB costs less than corn, has less price volatility because it has fewer inputs (e.g., lower energy costs) and is not tied to the food market.

Of larger concern is that commercializing lignocellulosic biofuels is technologically proven, but stymied by prohibitively high processing and capital costs. Opportunities to reduce these costs include developing higher-quality feedstocks, more active enzymes, better management of side products and using faster/higher yielding biocatalysts. Research at the USDA-ARS National Center for Agricultural Utilization Resarch (NCAUR) targets improvements in each of these areas.

In recent years, scientists at the NCAUR have made a number of technological advances toward overcoming the obstacles that impede the commercial production of fuel alcohol from biomass resources and a number of these resulted in patented inventions. For example, they discovered and developed new enzymes required for the breakdown of LCB to fermentable sugars that could significantly reduce the cost of this expensive processing step. They optimized the use of conventional and novel pretreatment strategies with these and other enzymes for the conversion of crop residues like wheat straw and for byproducts like corn fiber. They have engineered both bacterial and yeast biocatalysts that are able to make ethanol from all (not just some) of the sugars present in the feedstocks.

Because the required pretreatment processes generate fermentation inhibitors that are toxic to ethanol–producing microbes, NCAUR scientists came up with a novel bio-abatement process to detoxify these materials. They also engineered new biocatalysts that are more tolerant of these toxins. These technologies were ultimately combined into integrated bioprocesses that have been demonstrated at the pilot scale.

Additionally, NCAUR scientists, in collaboration with USDA-ARS plant breeders, have also applied these conversion technologies and tools to develop new energy crop varieties (e.g. switchgrass, forage sorghum, alfalfa) with improved bio-processing characteristics. These same approaches are now being employed to develop “next-generation” biofuels such as butanol and value-added co-products like xylitol. It is anticipated that the work being conducted by bioenergy researchers at NCAUR will continue to emphasize future biofuels, and they are currently working to adapt microbial fuel cell technology to produce hydrogen, the ultimate “next-generation” fuel. iBi

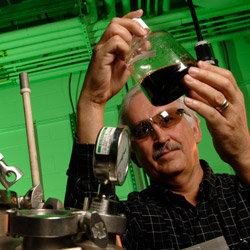

Michael Cotta, Ph.D., is a microbiologist/research leader in the Bioenergy Research Unit at the USDA ARS National Center for Agricultural Utilization Research.