Business Profile

Firefly Energy

One Peoria-based company is helping to revolutionize the industry of lead-acid batteries. Firefly Energy was named after the little insect that is not only part of a childhood pastime, but also a tiny natural miracle. “The firefly is the only entity to give off light without generating heat,” Mil Ovan, senior vice president and co-founder of Firefly Energy, said. “A firefly is an insect that is a 100 percent energy-converting machine.”

The company’s technologies began in the research and development labs at Caterpillar, Inc. Caterpillar uses batteries in many of its heavy machinery products, which put an extreme strain on the batteries being used. Soon Caterpillar began putting its name on the batteries used in the machines, but when consumers complained that the batteries didn’t live up to the Cat brand, the company decided it was time to improve its technology.

Kurt Kelley, now the chief technology officer of Firefly Energy, was assigned to address the two main reasons for failure of lead-acid batteries: corrosion and sulfation. He found the answer to these problems in a carbon-graphite foam. After Kelley’s discovery, the management at Caterpillar decided to provide funding to a separate company solely dedicated to developing this technology, the company which would become Firefly Energy. With Cat’s support, Firefly became the first spinoff project of Peoria NEXT, the local consortium that invests in new science and technology-based start-up businesses in the region.

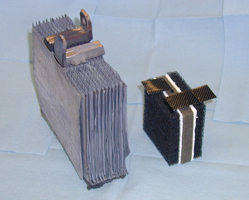

Firefly Energy has developed and patented two significant technologies that will deliver advanced battery performance for an entire spectrum of uses served by lead-acid, nickel and lithium-based chemistries. “The two technologies, called 3D and 3D2, involve the use of an extremely light-weight carbon-graphite foam, a porous three-dimensional material,” Ovan said. “The material is used in either flooded or valve-regulated lead-acid battery designs. Using this technology successively does away with the corrodible lead grids found in conventional lead-acid battery design and allows delivery of the full power potential of lead-acid chemistry for energy storage.

“This breakthrough delivers a formidable jump in power, energy and cycle life. The resulting products possess performance parameters comparable to advanced materials (lithium and nickel-based) batteries, but at costs far below these high-performance batteries. As the initial implementation phase of its carbon-graphite foam grid technology, Firefly’s 3D cell architecture involves replacing the conventional lead metal-based negative plate with a foam electrode. These products are configured in such a way as to be easily incorporated into existing lead-acid manufacturing processes possessed by all existing lead-acid manufacturers.”

Ovan goes on to add that the carbon-graphite foam enables the battery to perform at cooler temperatures—a key feature considering that lead batteries lose as much as 50 percent of their useful life for every 15 degrees the temperature rises above 70 degrees Fahrenheit.

While Firefly has been working on a prototype of the entire battery, their future intentions are to manufacture the key pieces to their battery design for use by other battery makers. “Lead-acid battery makers worldwide practice efficient and highly advanced manufacturing techniques and are skilled at seamless integrations,” Ovan said. “It is Firefly’s intention to use a facility in the Greater Peoria area to manufacture the pasted foam negative electrodes and furnish them to existing lead-acid manufacturing partners who will incorporate them into finished battery products. To all outward appearances, these batteries will be indistinguishable from currently available products.”

After spending three years at Illinois Central College’s North Campus, Firefly is set to announce plans to relocate to a much larger site. The company plans to keep its headquarters in the Peoria area, not only because of its link to Caterpillar, Inc., but also because of the benefits that Peoria has to offer. “What we have found is that we have been able to recruit both outside and inside Peoria the highly technical talent we need to grow the technology, and we can do it at a very cost-effective rate,” Ovan said. “If we were to move to either coast, there would be intellectual capacity, but it would be at an exorbitant price compared to what we can do here.”

On March 5, Firefly announced a contract with the United States Army to be involved in its Silent Watch program. “We just signed a $5 million contract with the U.S. Army to develop prototypes of our battery technology to assist the nation’s military defense efforts,” Ovan said. “Specifically, the Army will assess our carbon-graphite foam prototype batteries in their ‘Silent Watch’ program, which allows the military to perform reconnaissance in ground combat vehicles without being detected by the enemy. The goal of the Silent Watch program is to have enough electricity stored in a vehicle so that it can run on silent watch for anywhere from four to 72 hours, while providing continuous power to operate equipment without rapidly degrading the lifespan for the battery, and leaving enough battery power to restart the vehicle.”

The batteries developed by Firefly Energy appeared to conquer most of the problems encountered by the Army in previous tests. “Prior battery tests conducted by the Army in Yuma, Arizona, indicated a wide gap between requirements and the ability of current battery solutions (lead-acid, nickel and lithium) to meet the needs of the program,” Ovan said. “Our battery can fill that gap.”

While Firefly is helping military vehicles perform more efficiently, their technologies may also help in the effort to make hybrid vehicles more common and efficient. “The overnight plugin variety of hybrid electric vehicle is well-suited for future applications of Firefly Energy’s carbon-graphite foam lead-acid battery,” Ovan said. “It will be more energy-efficient, lighter in weight and less likely to corrode than today’s lead-acid batteries, which aren’t suitable for electric and hybrid vehicles, and will be less expensive than either the nickel metal hydride batteries currently used in hybrid electric vehicles or the lithium batteries contemplated for future use. These vehicles could be powered by an inexpensive battery pack which can be recharged at night, in the garage, during off-peak electric consumption hours and for the equivalent of about 50 cents per gallon.”

A plug-in hybrid has the ability to run on either battery power or an internal combustion engine. Plug-in hybrids have a larger battery than those of conventional hybrid electric vehicles and can be recharged by simply plugging the unit into an appropriate outlet. They can go anywhere from 20 to 60 miles before needing to be recharged. Once the battery is depleted, the gasoline engine then takes over. While 20 to 60 miles does not seem to be that far, research from the Electric Power Research Institute shows that on average, half of all U.S. consumer vehicles are driven 22 miles or less daily.

“More widespread adoption of plug-in hybrid vehicles would not necessitate changes to America’s existing gas station infrastructure, can offer home-based battery recharging at a low cost, can better utilize the nation’s low-load nighttime electrical grid and deliver a pure zero-emission capability,” Ovan said.

The carbon-graphite foam plate in the batteries also helps the environment, replacing the heavy, corrosion-prone lead grids which comprise up to 70 percent of a typical lead-acid battery’s weight with a non-toxic material. Therefore, there’s less lead to recycle at the end of its life. The batteries are smaller and have a longer life, as the porous material used provides more surface area for the energy-generating chemistry. The batteries also have an infrastructure that is basically self-recycling, reducing human exposure risk and hazardous waste generation. The carbon-graphite foam is burned away, actually becoming fuel for the battery.

Firefly Energy is one of the Peoria area’s great success stories of recent years. It won the Frost & Sullivan 2006 Technology Innovation Award and was named one of the top 200 private technology companies in North America for 2006. For more information about the company or its technologies, visit www.fireflyenergy.com. IBI

The company’s technologies began in the research and development labs at Caterpillar, Inc. Caterpillar uses batteries in many of its heavy machinery products, which put an extreme strain on the batteries being used. Soon Caterpillar began putting its name on the batteries used in the machines, but when consumers complained that the batteries didn’t live up to the Cat brand, the company decided it was time to improve its technology.

Kurt Kelley, now the chief technology officer of Firefly Energy, was assigned to address the two main reasons for failure of lead-acid batteries: corrosion and sulfation. He found the answer to these problems in a carbon-graphite foam. After Kelley’s discovery, the management at Caterpillar decided to provide funding to a separate company solely dedicated to developing this technology, the company which would become Firefly Energy. With Cat’s support, Firefly became the first spinoff project of Peoria NEXT, the local consortium that invests in new science and technology-based start-up businesses in the region.

Firefly Energy has developed and patented two significant technologies that will deliver advanced battery performance for an entire spectrum of uses served by lead-acid, nickel and lithium-based chemistries. “The two technologies, called 3D and 3D2, involve the use of an extremely light-weight carbon-graphite foam, a porous three-dimensional material,” Ovan said. “The material is used in either flooded or valve-regulated lead-acid battery designs. Using this technology successively does away with the corrodible lead grids found in conventional lead-acid battery design and allows delivery of the full power potential of lead-acid chemistry for energy storage.

“This breakthrough delivers a formidable jump in power, energy and cycle life. The resulting products possess performance parameters comparable to advanced materials (lithium and nickel-based) batteries, but at costs far below these high-performance batteries. As the initial implementation phase of its carbon-graphite foam grid technology, Firefly’s 3D cell architecture involves replacing the conventional lead metal-based negative plate with a foam electrode. These products are configured in such a way as to be easily incorporated into existing lead-acid manufacturing processes possessed by all existing lead-acid manufacturers.”

Ovan goes on to add that the carbon-graphite foam enables the battery to perform at cooler temperatures—a key feature considering that lead batteries lose as much as 50 percent of their useful life for every 15 degrees the temperature rises above 70 degrees Fahrenheit.

While Firefly has been working on a prototype of the entire battery, their future intentions are to manufacture the key pieces to their battery design for use by other battery makers. “Lead-acid battery makers worldwide practice efficient and highly advanced manufacturing techniques and are skilled at seamless integrations,” Ovan said. “It is Firefly’s intention to use a facility in the Greater Peoria area to manufacture the pasted foam negative electrodes and furnish them to existing lead-acid manufacturing partners who will incorporate them into finished battery products. To all outward appearances, these batteries will be indistinguishable from currently available products.”

After spending three years at Illinois Central College’s North Campus, Firefly is set to announce plans to relocate to a much larger site. The company plans to keep its headquarters in the Peoria area, not only because of its link to Caterpillar, Inc., but also because of the benefits that Peoria has to offer. “What we have found is that we have been able to recruit both outside and inside Peoria the highly technical talent we need to grow the technology, and we can do it at a very cost-effective rate,” Ovan said. “If we were to move to either coast, there would be intellectual capacity, but it would be at an exorbitant price compared to what we can do here.”

On March 5, Firefly announced a contract with the United States Army to be involved in its Silent Watch program. “We just signed a $5 million contract with the U.S. Army to develop prototypes of our battery technology to assist the nation’s military defense efforts,” Ovan said. “Specifically, the Army will assess our carbon-graphite foam prototype batteries in their ‘Silent Watch’ program, which allows the military to perform reconnaissance in ground combat vehicles without being detected by the enemy. The goal of the Silent Watch program is to have enough electricity stored in a vehicle so that it can run on silent watch for anywhere from four to 72 hours, while providing continuous power to operate equipment without rapidly degrading the lifespan for the battery, and leaving enough battery power to restart the vehicle.”

The batteries developed by Firefly Energy appeared to conquer most of the problems encountered by the Army in previous tests. “Prior battery tests conducted by the Army in Yuma, Arizona, indicated a wide gap between requirements and the ability of current battery solutions (lead-acid, nickel and lithium) to meet the needs of the program,” Ovan said. “Our battery can fill that gap.”

While Firefly is helping military vehicles perform more efficiently, their technologies may also help in the effort to make hybrid vehicles more common and efficient. “The overnight plugin variety of hybrid electric vehicle is well-suited for future applications of Firefly Energy’s carbon-graphite foam lead-acid battery,” Ovan said. “It will be more energy-efficient, lighter in weight and less likely to corrode than today’s lead-acid batteries, which aren’t suitable for electric and hybrid vehicles, and will be less expensive than either the nickel metal hydride batteries currently used in hybrid electric vehicles or the lithium batteries contemplated for future use. These vehicles could be powered by an inexpensive battery pack which can be recharged at night, in the garage, during off-peak electric consumption hours and for the equivalent of about 50 cents per gallon.”

A plug-in hybrid has the ability to run on either battery power or an internal combustion engine. Plug-in hybrids have a larger battery than those of conventional hybrid electric vehicles and can be recharged by simply plugging the unit into an appropriate outlet. They can go anywhere from 20 to 60 miles before needing to be recharged. Once the battery is depleted, the gasoline engine then takes over. While 20 to 60 miles does not seem to be that far, research from the Electric Power Research Institute shows that on average, half of all U.S. consumer vehicles are driven 22 miles or less daily.

“More widespread adoption of plug-in hybrid vehicles would not necessitate changes to America’s existing gas station infrastructure, can offer home-based battery recharging at a low cost, can better utilize the nation’s low-load nighttime electrical grid and deliver a pure zero-emission capability,” Ovan said.

The carbon-graphite foam plate in the batteries also helps the environment, replacing the heavy, corrosion-prone lead grids which comprise up to 70 percent of a typical lead-acid battery’s weight with a non-toxic material. Therefore, there’s less lead to recycle at the end of its life. The batteries are smaller and have a longer life, as the porous material used provides more surface area for the energy-generating chemistry. The batteries also have an infrastructure that is basically self-recycling, reducing human exposure risk and hazardous waste generation. The carbon-graphite foam is burned away, actually becoming fuel for the battery.

Firefly Energy is one of the Peoria area’s great success stories of recent years. It won the Frost & Sullivan 2006 Technology Innovation Award and was named one of the top 200 private technology companies in North America for 2006. For more information about the company or its technologies, visit www.fireflyenergy.com. IBI